Index Drives

- Globoidal Cam Indexers

- Rotary Table Indexers

- Heavy Duty Indexers

- Parallel Cam Indexers

- Servo-Mechanical Indexers

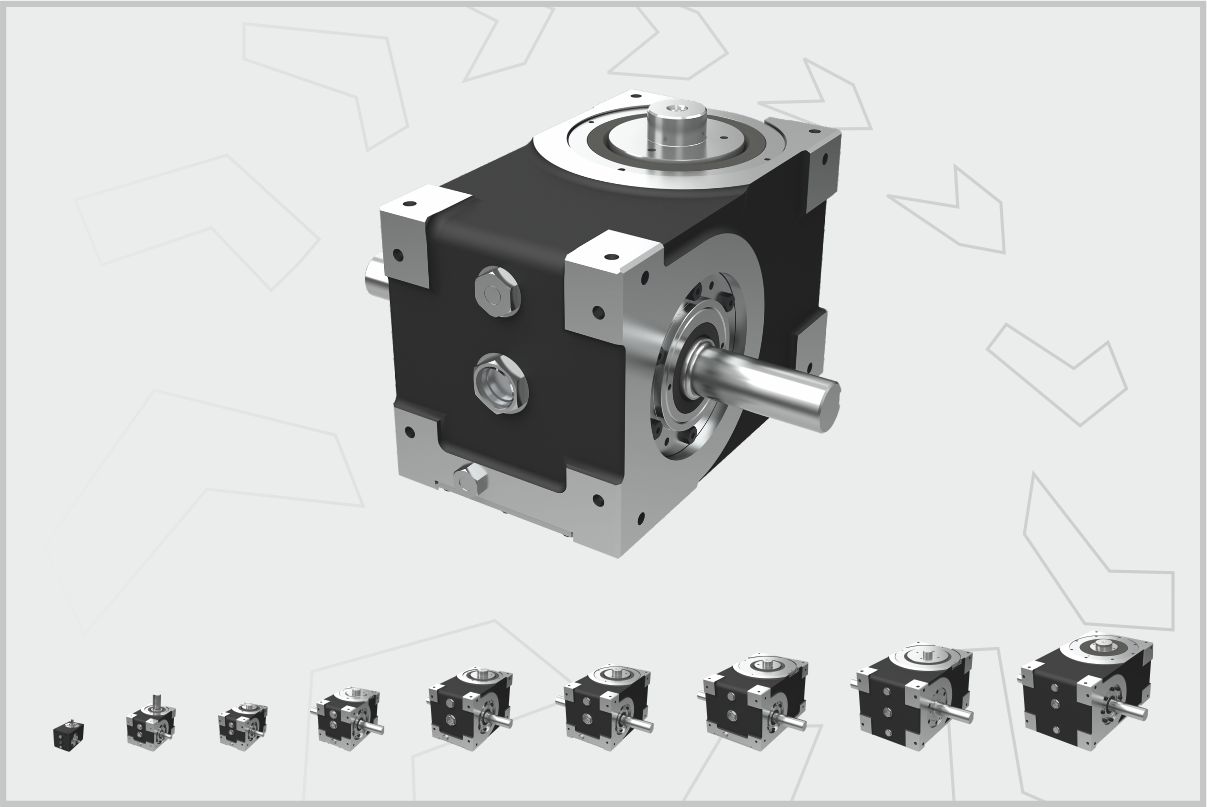

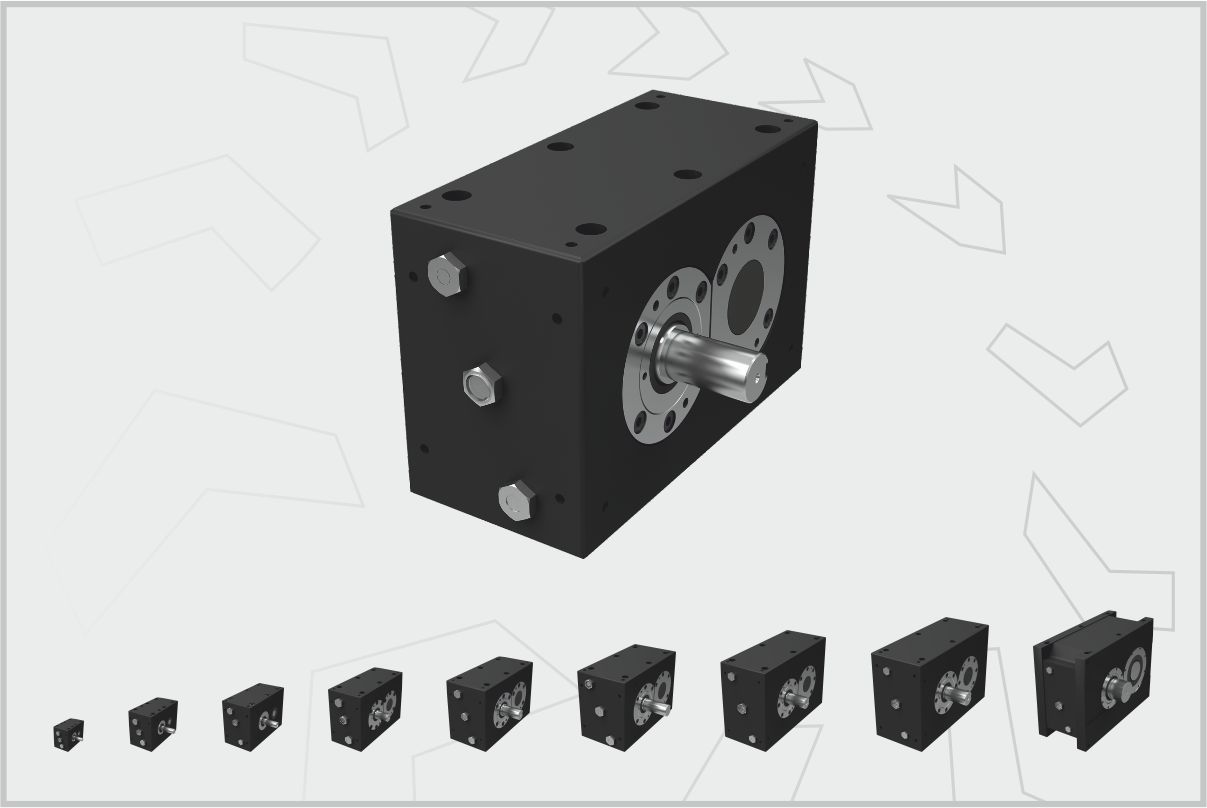

Globoidal Cam Indexers [GC Type]

|

GC Type

CE Certified Product – EN ISO 12100:2010

Globoidal Cam Indexers

Right angle indexers are typically used for continuously running applications with cams designed to match the indexing and idle times without stopping the motor. These are versatile units suitable for a wide range of applications.

Selection Criteria: GC Type

Models:GC50, GC80, GC95, GC110, GC140, GC150, GC180, GC200, GC250

Most models available with optional Output: S= Shaft Output, F= Flanged Output & H= Hollow Output

Larger sizes available in Mechanism Only | Indexer + Geared Motor Package – available on request.

Mechanism Type: Globoidal

Arrangement of shafts: Crossed

|

Features:

Number of Stops:

Indexes/minute: <1000

|

Oscillating Motion:

Direction of rotation:

Mounting position:

Accuracy:

|

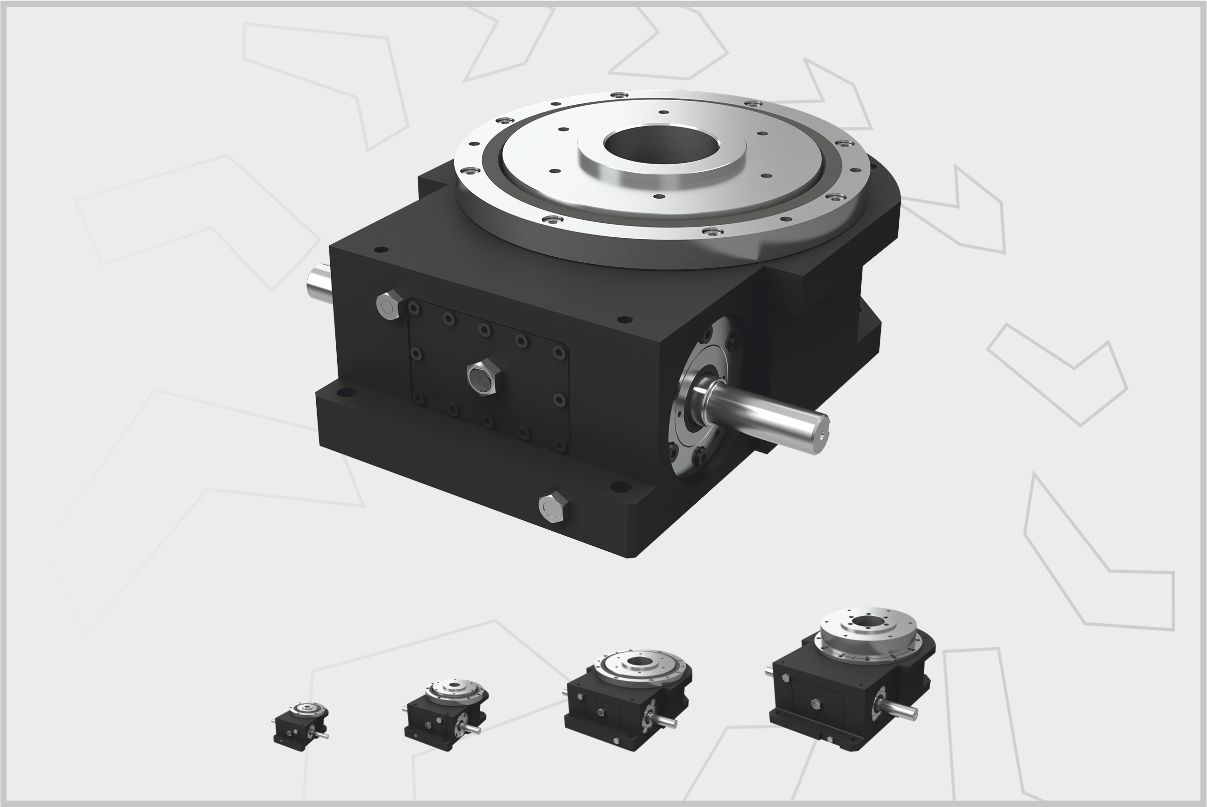

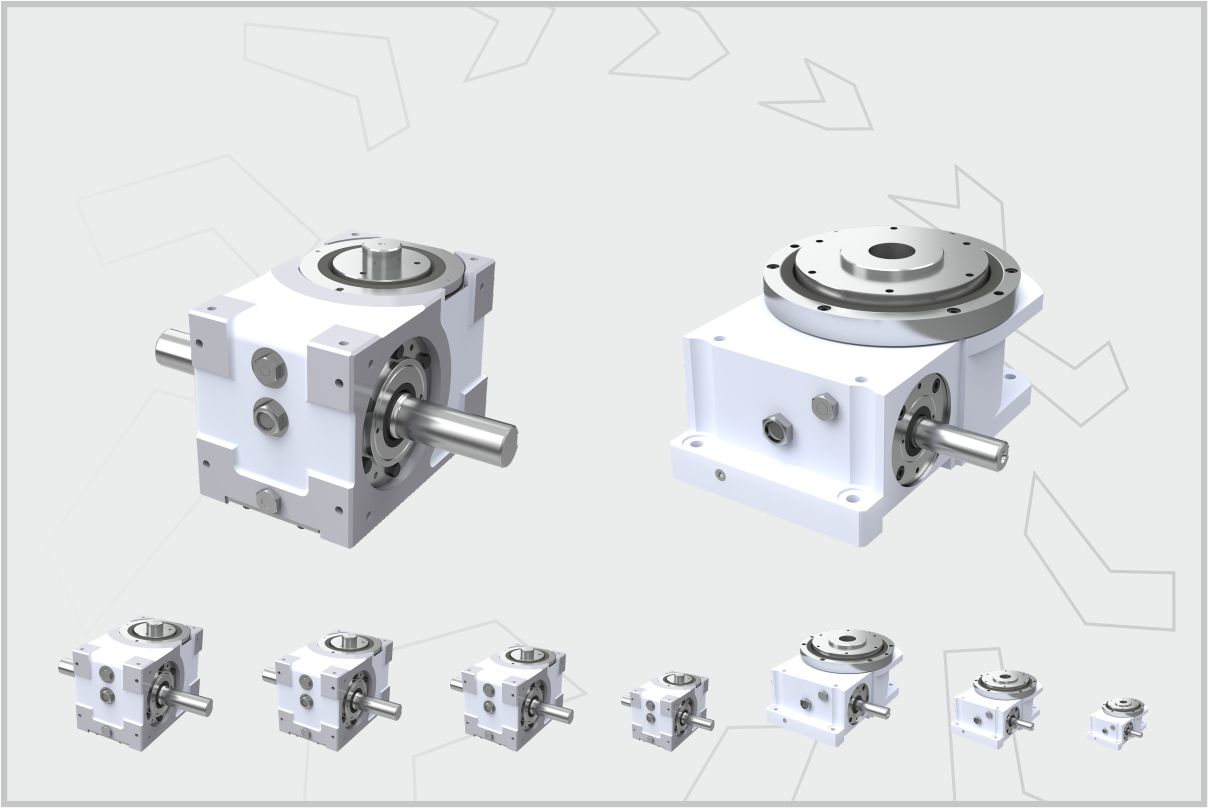

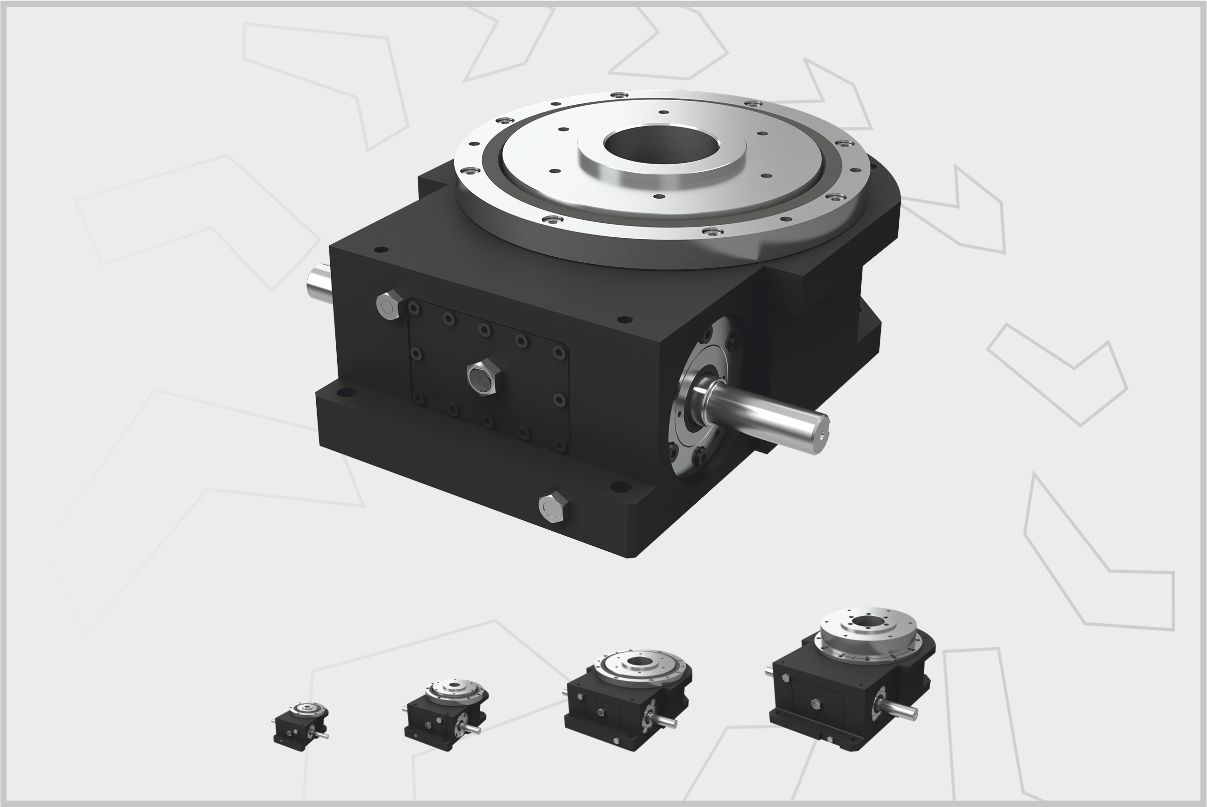

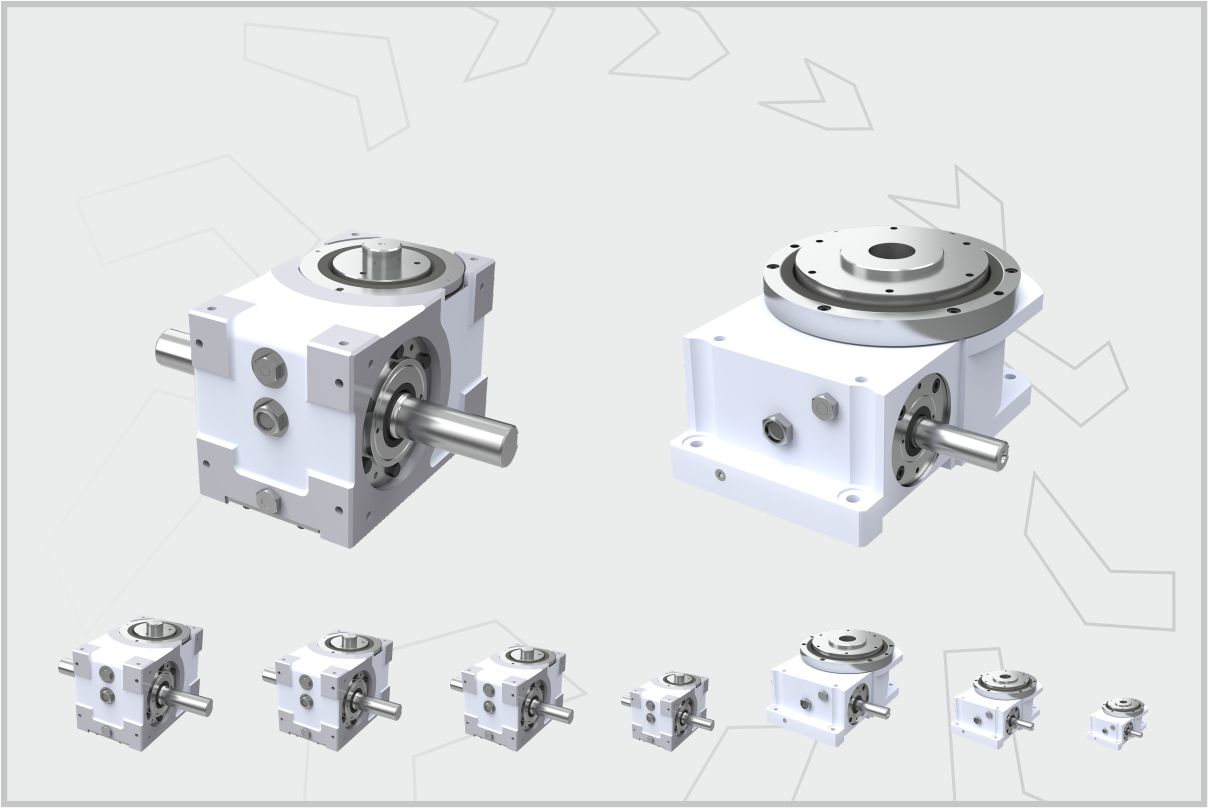

Rotary Table Indexers [RT Type]

|

RT Type

CE Certified Product – EN ISO 12100:2010

Rotating Table Indexers

Rotary indexing units with globoidal cam mechanisms are ideal for dial plate indexing. Each have stationary center through bores for routing supply lines and dual flanges for mounting a stationary dial over the indexing dial.

Selection Criteria: RT Type

Models:

RT85, RT100, RT150, RT240

[Also available as servo-mechanical indexer for precise control and flexibility]

Indexer + Geared Motor Package – available on request.

Mechanism Type: Globoidal

Arrangement of shafts: Crossed

|

Features:

Number of Stops:

Indexes/minute: <200

|

Oscillating Motion:

Direction of rotation:

Mounting position:

Accuracy:

|

Heavy Duty Indexers [HD Type]

|

HD Type

CE Certified Product – EN ISO 12100:2010

Heavy Duty Indexers

HD type indexers are very accurate and reliable rotary tables suitable for heavy duty applications. The robust and compact design provides a big dial plate and a large center hole.

Selection Criteria: HD Type

Models:

HD190, HD265, HD315

Indexer + Geared Motor Package – available on request.

Mechanism Type: Globoidal

|

Features:

Number of Stops:

Indexes/minute: <300

|

Oscillating Motion:

Direction of rotation:

Mounting position:

Accuracy:

|

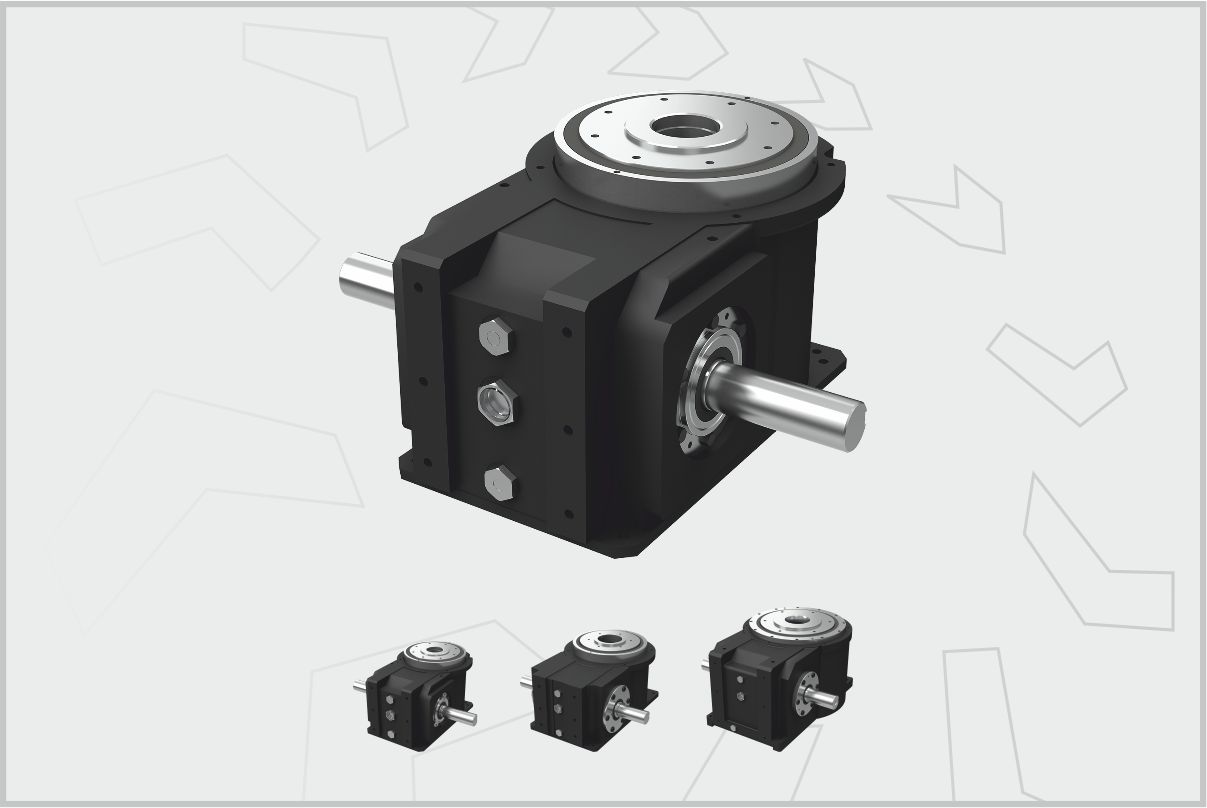

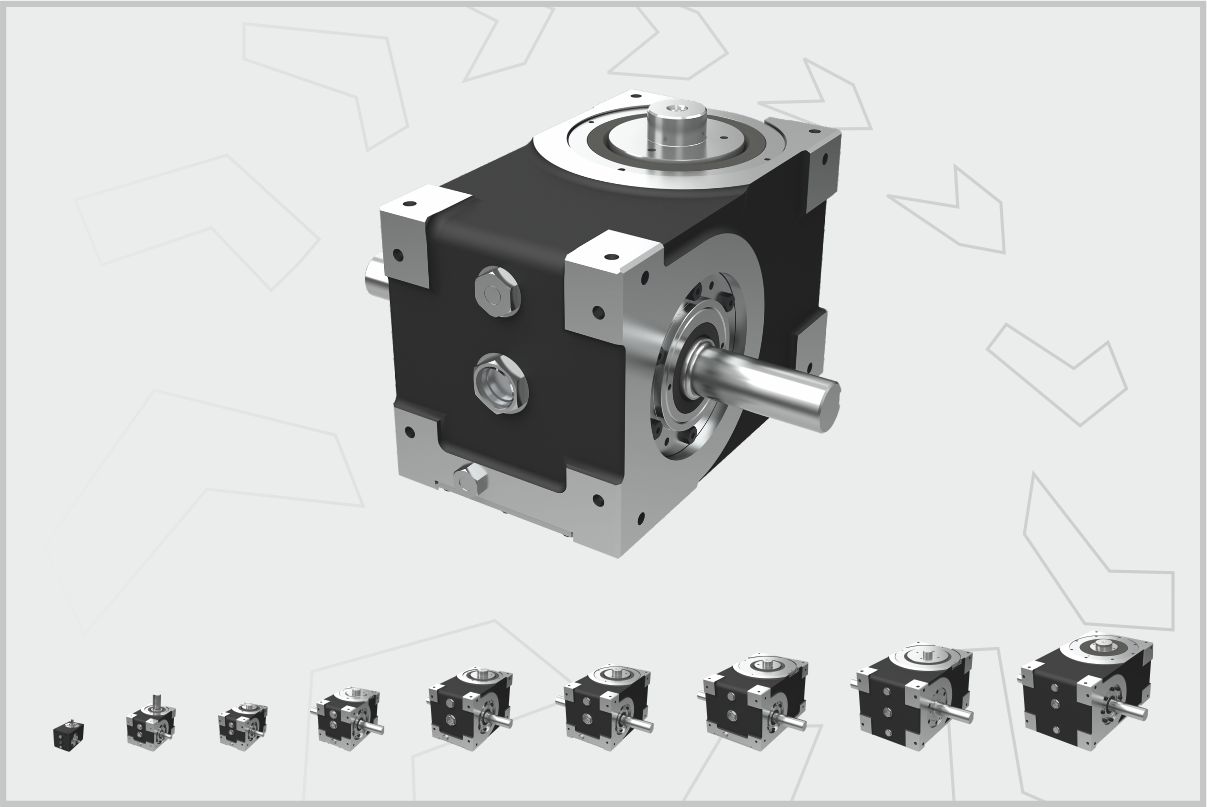

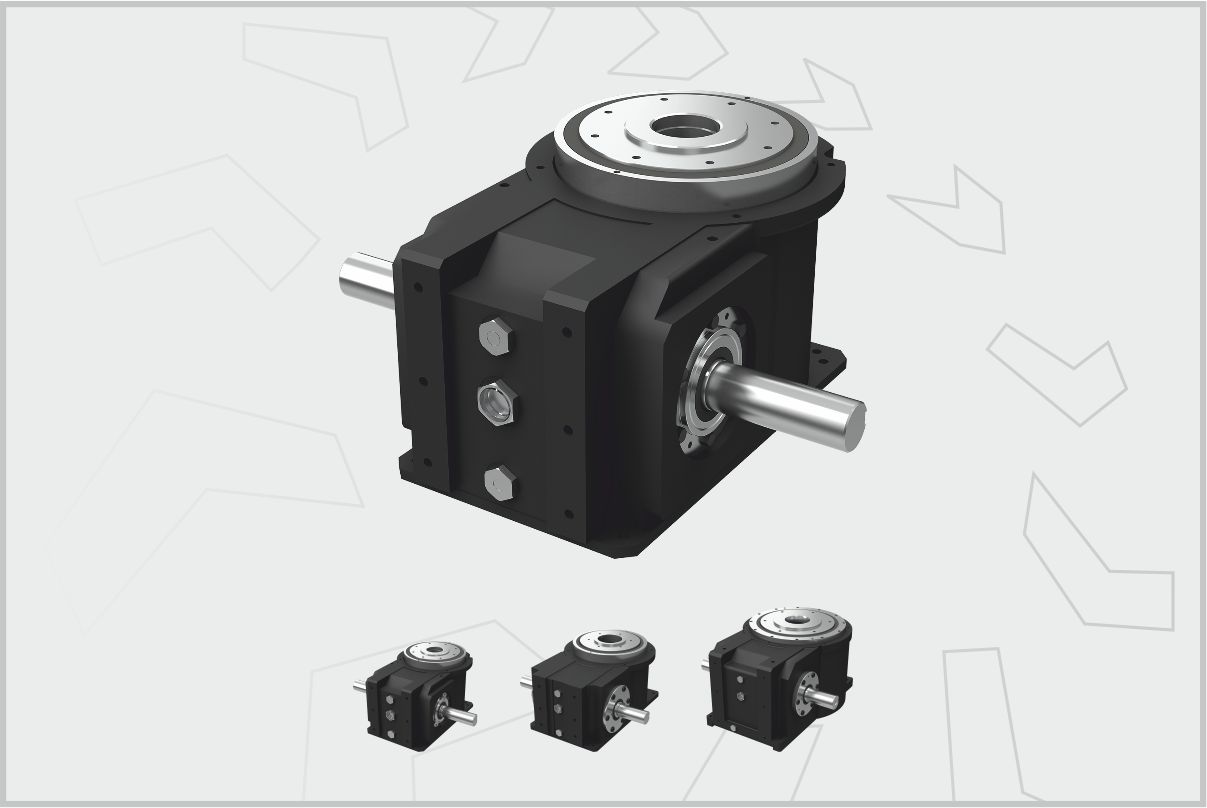

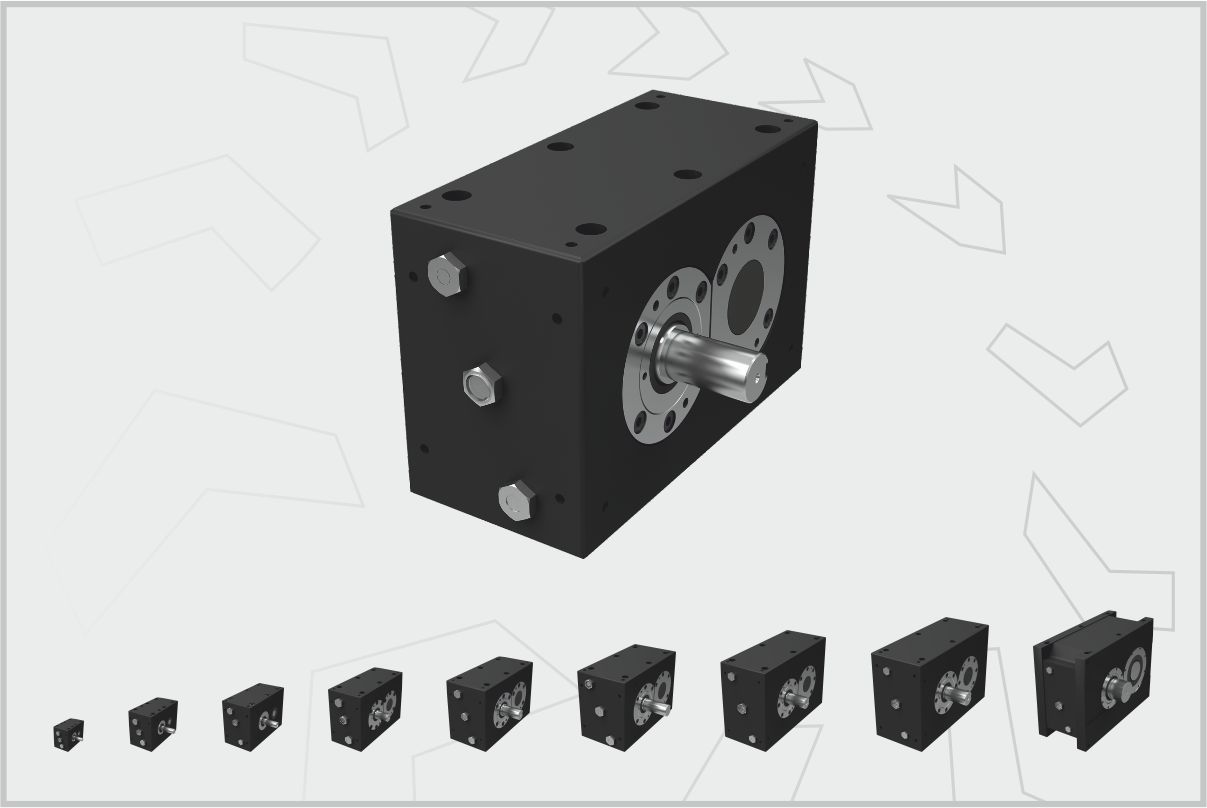

Parallel Cam Indexers [PC Type]

|

PC Type

CE Certified Product – EN ISO 12100:2010

Parallel Cam Indexers

Parallel indexers have the input and output shafts located parallel. They are commonly used to drive feed conveyors or packaging machinery when a line shaft needs to index. Feeding and idle times are usually configured to match the supported machinery with the line shaft or drive motor running continuously.

Selection Criteria: PC Type

Models:

PC40, PC50, PC63, PC80, PC100, PC125, PC130, PC160, PC200, PC250

Larger sizes available in Mechanism Only | Indexer + Geared Motor Package – available on request.

Mechanism Type: Parallel

Arrangement of shafts: Parallel

|

Features:

Number of Stops:

Indexes/minute: < 200

|

Oscillating Motion:

Direction of rotation:

Mounting position:

Accuracy:

|

Servo-Mechanical Indexers [SM Type]

|

SM Type

CE Certified Product – EN ISO 12100:2010

Servo-Mechanical Indexers

The SM Series of indexers are servo-mechanical indexers designed for application where different output motions are required on the same table. A standard mechanical cam indexer is driven by an inline or right-angle servo reducer matching customers speed and load requirements. COMBINING THE BEST OF THE OLD, WITH THE NEW – Compatible with multiple brands of servo.

Selection Criteria: SM Type

Model:

RT100-SM

Standard ratio 8:1 – others available on request | Available in other frame sizes – on request.

Mechanism Type: Globoidal

Arrangement of shafts: Crossed

Features:

Number of Stops:

Indexes/minute:

Indexing Angle:

|

Oscillating Motion:

Direction of rotation:

Mounting position:

Accuracy:

|

- Globoidal Cam Indexers

- Rotary Table Indexers

- Heavy Duty Indexers

- Parallel Cam Indexers

- Servo-Mechanical Indexers

Globoidal Cam Indexers [GC Type]

GC Type

CE Certified Product – EN ISO 12100:2010

Globoidal Cam Indexers

Right angle indexers are typically used for continuously running applications with cams designed to match the indexing and idle times without stopping the motor. These are versatile units suitable for a wide range of applications.

Selection Criteria: GC Type

Models:

GC50, GC80, GC95, GC110, GC140, GC150, GC180, GC200, GC250

Most models available with optional Output: S= Shaft Output, F= Flanged Output & H= Hollow Output

Larger sizes available in Mechanism Only | Indexer + Geared Motor Package – available on request.

Mechanism Type: Globoidal

Arrangement of shafts: Crossed

Features:

- Through hardened and CNC ground steel cam

- Cast iron housing for rigidity and zero vibration

- Shaft and hollow output are optional on most models

- Double dwell cam for high speed indexers

Number of Stops:

- (0) 1 to 32

- “0” equals constant speed cam

- (with additional reduction gear, higher number of stops possible)

Indexes/minute: <1000

Indexing Angle:

- 90° to 330°

- depending on number of stops

Oscillating Motion:

- Upto 150° Indexing angle

- (special motion profiles over full 360° output)

Direction of rotation:

- Clockwise, counterclockwise, reversing

Mounting position:

- Horizontal, vertical, upside down

Accuracy:

- Refer to model specific page in our Technical Product Catalogue

Rotary Table Indexers [RT Type]

RT Type

CE Certified Product – EN ISO 12100:2010

Rotating Table Indexers

Rotary indexing units with globoidal cam mechanisms are ideal for dial plate indexing. Each have stationary center through bores for routing supply lines and dual flanges for mounting a stationary dial over the indexing dial.

Selection Criteria: RT Type

Models:

RT85, RT100, RT150, RT240

[Also available as servo-mechanical indexer for precise control and flexibility]

Indexer + Geared Motor Package – available on request.

Mechanism Type: Globoidal

Arrangement of shafts: Crossed

Features:

- Through hardened and CNC ground steel cam

- Cast iron housing for rigidity and zero vibration

- High degree of stability for dial plate applications

- Through hole for wires and utilities

- Large output flange

Number of Stops:

- (0) 3 to 32

- “0” equals constant speed cam

Indexes/minute: <200

Indexing Angle:

- 90° to 330°

- depending on number of stops

Oscillating Motion:

- limited possibilities

Direction of rotation:

- Clockwise, counterclockwise, reversing

Mounting position:

- Horizontal, vertical, upside down

Accuracy:

- Refer to model specific page in our Technical Product Catalogue

Heavy Duty Indexers [HD Type]

HD Type

CE Certified Product – EN ISO 12100:2010

Heavy Duty Indexers

HD type indexers are very accurate and reliable rotary tables suitable for heavy duty applications. The robust and compact design provides a big dial plate and a large center hole.

Selection Criteria: HD Type

Models:

HD190, HD265, HD315

Indexer + Geared Motor Package – available on request.

Mechanism Type: Globoidal

Arrangement of shafts: Crossed

Features:

- Through hardened and CNC ground steel cam

- Cast iron housing for rigidity and zero vibration

- High precision heavy duty cam followers

- Large output mounting surface

- Large centre thru-hole

Number of Stops:

- 1 to 32

Indexes/minute: <300

Indexing Angle:

- 90° to 330°

- depending on number of stops

Oscillating Motion:

- Upto 150° Indexing angle

Direction of rotation:

- Clockwise, counterclockwise, reversing

Mounting position:

- Horizontal, vertical, upside down

Accuracy:

- Refer to model specific page in our Technical Product Catalogue

Parallel Cam Indexers [PC Type]

PC Type

CE Certified Product – EN ISO 12100:2010

Parallel Cam Indexers

Parallel indexers have the input and output shafts located parallel. They are commonly used to drive feed conveyors or packaging machinery when a line shaft needs to index. Feeding and idle times are usually configured to match the supported machinery with the line shaft or drive motor running continuously.

Selection Criteria: PC Type

Models:

PC40, PC50, PC63, PC80, PC100, PC125, PC130, PC160, PC200, PC250

Larger sizes available in Mechanism Only | Indexer + Geared Motor Package – available on request.

Mechanism Type: Parallel

Arrangement of shafts: Parallel

Features:

- Through hardened and conjugate steel cam

- High precision cam followers

- Rigid housing – zero vibrations

- Double ended output shafts are optional on most models

Number of Stops:

- 1 to 8

(with additional reduction gear, higher number of stops possible)

Indexes/minute: < 200

Indexing Angle:

- 90° to 330°

- depending on number of stops

Oscillating Motion:

- Upto 45° Indexing angle

Direction of rotation:

- Clockwise, counterclockwise, reversing

Mounting position:

- Horizontal, vertical, upside down

Accuracy:

- Refer to model specific page in our Technical Product Catalogue

Servo-Mechanical Indexers [SM Type]

SM Type

CE Certified Product – EN ISO 12100:2010

Servo-Mechanical Indexers

The SM Series of indexers are servo-mechanical indexers designed for application where different output motions are required on the same table. A standard mechanical cam indexer is driven by an inline or right-angle servo reducer matching customers speed and load requirements. COMBINING THE BEST OF THE OLD, WITH THE NEW – Compatible with multiple brands of servo.

Selection Criteria: SM Type

Model:

RT100-SM

Standard ratio 8:1 – others available on request | Available in other frame sizes – on request.

Mechanism Type: Globoidal

Arrangement of shafts: Crossed

Features:

- Through hardened and CNC ground steel Globoidal Cam

- Preloaded Mechanism

- Cast iron housing for rigidity and zero vibration

- Through hole for wires and utilities

- Indexing flexibility / Freely-programmable

- 4:1 to 12:1 ratios options available

- Compatible with multiple brands of servo motor

Number of Stops:

- “0” equals constant speed cam (servo controlled)

Indexes/minute:

- <200

Indexing Angle:

- 360° (constant lead cam)

Oscillating Motion:

- Unlimited possibilities (servo controlled)

Direction of rotation:

- Clockwise, counterclockwise, reversing (servo controlled)

Mounting position:

- Horizontal, vertical

Accuracy:

- Refer to model specific page in our Technical Product Catalogue